Importance of Proper Steam Distribution Designing:

Once you’ve invested in a steam design system and if that’s operating not efficiently, it makes economic sense to select proper professionals before designing of that system. For companies where in-house engineering skills are in short supply or where limited steam engineering experience is available, outsourcing your steam distribution designing services can prove to be a highly cost effective solution for keeping downtime to minimum and increasing steam efficiency.

Benefits to your Business

- Increasing steam efficiency

- Maintaining high plant performance.

- Preventative maintenance cost will decrease.

- Reduction in breakdowns and downtime.

- Savings and benefits become visible through proper designing of steam distribution system.

Our Approach about Steam Distribution Systems:

Steam is used in many industrial processes and is often a source of large amounts of wasted energy and money. Industrial facilities can reduce steam energy consumption by 20% through simple improvements in their steam system.

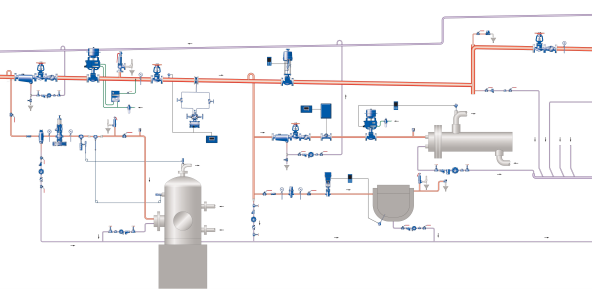

The primary purpose of an effective steam distribution system is to link the output of the steam generation system to the steam end use equipment. The distribution system should supply high-quality steam to the end use equipment at the required rate and pressure, and with the minimum heat loss. Key components include steam distribution piping, valves, and flanges, distribution system insulation, steam traps, air vents, drip legs, and strainers. The key inputs include steam conditions (pressure and quality) from the generation system and outputs include steam distribution outlet mass flow and pressure, distribution outlet steam quality.

Why Select Us:

- We selecting proper size of pipes and steam traps.

- We recommending size of insulation for all distribution system pipes, flanges, and valves.

- We ensuring that steam mains are properly laid out, sized, adequately drained, and adequately air vented.

- We ensuring that Distribution System piping are correctly sized to produce the appropriate system pressure drops.

- We ensuring that distribution system piping is adequately supported, guided, and anchored, and that appropriate allowances are made for pipe expansion at operating temperatures.