The flue gases arising from the combustion contain CO2, oxide or soot particles, amongst other things. These pollute the environment, have a negative effect on the climate and conceal numerous health risks for human beings. That is why it is absolutely essential to design combustion processes in a more efficient way, to optimize thermal processes and above all to reduce emissions. When controlling industrial plants, it is important to achieve a balance between efficient operation and the least possible environmental pollution. Instruments for flue gas analysis and emission measurement play an important role in this process. They help you to increase efficiency, to comply with statutory emission limit values and they are indispensable when it comes to monitoring and optimizing thermal manufacturing processes.

Measuring the exhaust gas is an excellent way to optimize fuel and air input. A flue gas analyzer will enable you to measure the concentrations of various gases and adjust burners on a boiler to help achieve optimal combustion. Efficient combustion also reduces emission of pollutants such as nitric oxide (NO), nitrogen dioxide (NO2), sulfur dioxide (SO2), and particulate matter. A gas analyzer will also help measure various gas pollutants in the exhaust for environmental reasons.

Furnaces, heaters, and boilers burn fuel in the presence of oxygen to produce heat. Achieving an intelligent balance of fuel and air will provide the most efficient combustion and highest cost savings. Use flue gas analysis to test the combustion efficiency of boilers and make appropriate adjustments to increase efficiency back to design levels.

Benefits

- Reduced fuel consumption.

- Lower energy costs.

- Increased domestic hot water capacity.

- Extended life for boilers.

- Reduced time to heat water.

- Cleaner boiler operation for increased reliability.

GEA Considerations

- We have qualified Energy Engineers for doing this test.

- We have latest TESTO 320/340 with updated calibration certificate.

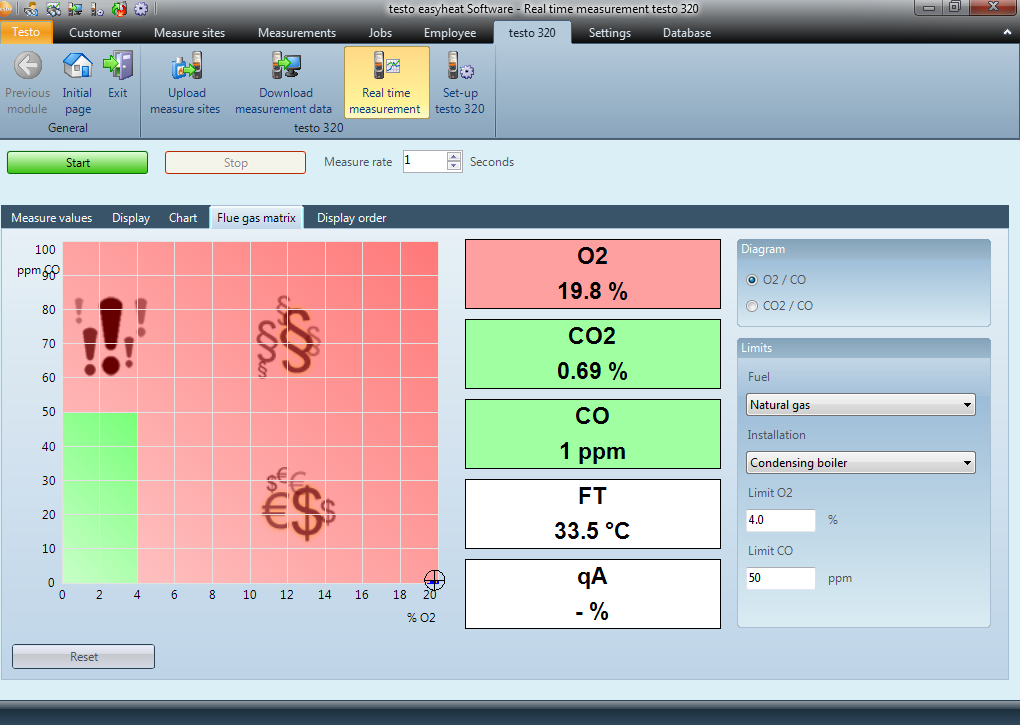

- Sharing test result on TESTO Easy heat software. (World’s first software for Flue Gas Analysis only)

- Providing test results on test location through infrared printer.

- Besides testing, GEA team will watch for the following conditions:

- A soft, lazy yellow flame.

- A hard blue flame.

- Dirty or sooty heat exchanger surfaces.

- Damaged combustion chamber walls.

- Back drafting.

- Flame roll out.

- Condensation in boiler or vent.